In the world of modern engineering and automation, understanding the concept of pneumatics is essential. Pneumatic systems play a vital role in powering machinery, automating processes, and simplifying industrial operations. By mastering the pneumatic definition and its applications, professionals and learners alike can enhance their technical knowledge and contribute to greater efficiency and innovation.

Understanding the Pneumatic Definition

The term pneumatic comes from the Greek word pneuma, meaning air or wind. In simple terms, pneumatics refers to the use of compressed air or gas to generate mechanical motion or perform work. Pneumatic systems rely on air pressure to operate various tools, equipment, and control systems efficiently.

Key elements of a pneumatic system include:

- Compressor: Produces and stores compressed air.

- Valves: Control the direction and flow of air.

- Actuators: Convert air pressure into motion.

- Pipes and fittings: Deliver air to different components.

Why Learning Pneumatics Matters

Understanding pneumatics offers valuable insights into how many industrial and mechanical systems function. It provides the foundation for designing, maintaining, and improving automation technologies used worldwide.

Benefits of mastering pneumatics include:

- Enhanced technical skills: Builds knowledge in pressure control and motion systems.

- Career advancement: Opens opportunities in automation, manufacturing, and robotics.

- Problem-solving ability: Helps identify and fix system inefficiencies.

- Sustainability awareness: Encourages the use of clean and energy-efficient systems.

Applications of Pneumatic Systems

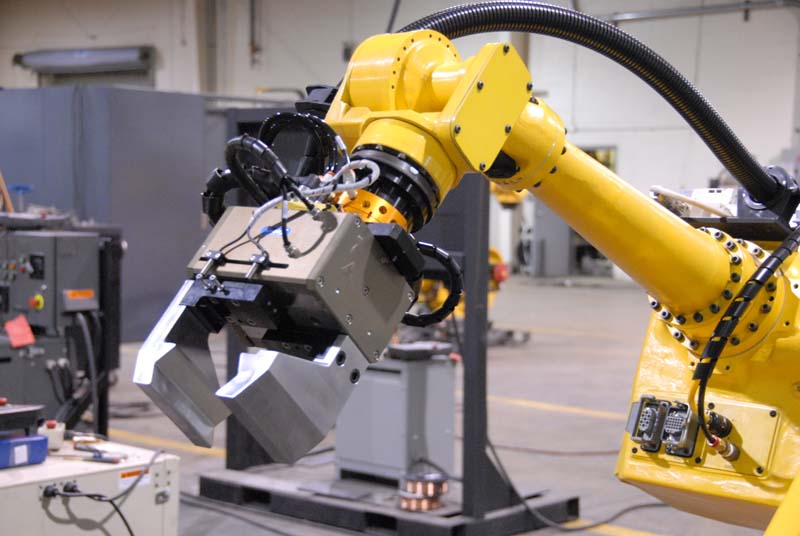

Pneumatic technology is used across countless sectors due to its safety, reliability, and versatility. It powers everyday tools and advanced industrial systems alike, making it a cornerstone of modern automation.

Common applications include:

- Operating air-powered tools and machinery.

- Controlling assembly line equipment in manufacturing.

- Managing braking and suspension systems in vehicles.

- Regulating medical devices and laboratory instruments.

Advantages of Pneumatic Systems

Pneumatics offer numerous benefits that make them a preferred choice for engineers and technicians. Their simplicity, low maintenance requirements, and environmental friendliness make them ideal for both large-scale and small-scale applications.

Key advantages include:

- Clean and safe operation: Uses air instead of hazardous fluids.

- High reliability: Functions effectively under extreme conditions.

- Cost-efficiency: Offers long-term value with minimal upkeep.

- Energy-efficient design: Reduces waste and promotes sustainability.

Expanding Knowledge Through Continuous Learning

Mastering the pneumatic definition is more than understanding how air pressure creates motion it is about grasping a vital concept that supports automation, efficiency, and innovation. Continuous learning in pneumatic systems helps professionals stay ahead in the rapidly evolving fields of technology and engineering.

By exploring the principles, applications, and advantages of pneumatics, individuals can develop stronger technical expertise, contribute to industry growth, and embrace the future of smart mechanical solutions.